Pickleball is no longer a niche sport. Across schools, clubs, gated communities, sports academies, and commercial complexes, dedicated courts are being built at record speed. As demand grows, the focus is shifting from “just building a court” to selecting the right pickleball court flooring that ensures durability, player safety, and long-term value.

In 2026, facility owners are prioritizing performance-driven surfaces, weather resistance, low maintenance, and compliance with official pickleball court dimensions. This complete guide covers everything needed to make informed decisions—from choosing the right pickleball court material to understanding the full pickleball court construction process.

Understanding Official Pickleball Court Dimensions

Before discussing flooring systems, it is important to understand standard pickleball court dimensions. According to official guidelines from organizations such as USA Pickleball and the International Federation of Pickleball:

- Court size: 20 feet wide x 44 feet long

- Non-volley zone (“kitchen”): 7 feet from the net on each side

- Recommended total play area: 30 x 60 feet minimum

- Preferred total area for tournaments: 34 x 64 feet

Why does this matter for flooring? Because surface texture, base slope, and line marking precision must align exactly with these measurements. Poor planning during pickleball court construction often leads to incorrect slopes, uneven bounce, or misaligned markings.

In 2026, precision planning and surface engineering are key components of professional installations.

Why Pickleball Court Flooring Matters More Than Ever

The right pickleball court flooring directly impacts:

- Ball bounce consistency

- Player traction and grip

- Shock absorption

- Surface lifespan

- Maintenance costs

Unlike casual recreational surfaces, modern pickleball courts are built for high-frequency usage. Clubs may host tournaments, coaching sessions, and daily public play. Inferior pickleball court material leads to cracks, fading, slippery surfaces, and expensive repairs within a few years.

High-performance synthetic acrylic systems are currently among the most preferred surfaces due to their balance of durability, playability, and cost-efficiency.

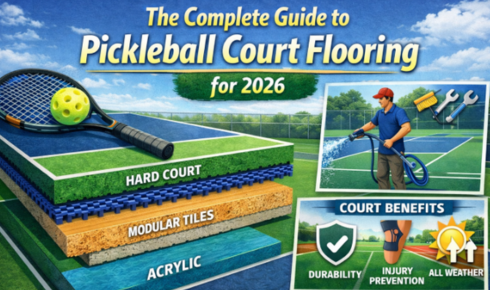

Types of Pickleball Court Flooring in 2026

1. Acrylic Synthetic Flooring (Most Preferred)

Acrylic-based pickleball court material is applied over a concrete or asphalt base. It consists of multiple layers including primer, resurfacer, cushion coats (optional), and textured topcoats.

Advantages:

- UV resistant

- Anti-slip texture

- Consistent ball bounce

- Custom color options

- Lower maintenance

This system is widely used in competitive facilities and is often recommended by experienced pickleball court builders.

2. Concrete Surface (Basic Option)

Plain concrete courts are budget-friendly but lack cushioning and surface texture. Over time, they develop cracks due to temperature changes.

Limitations:

- Hard on joints

- Slippery when wet

- Poor long-term durability without coatings

3. Modular Interlocking Tiles

Tile systems are portable and quick to install. They work well for temporary setups but may produce different ball bounce characteristics compared to acrylic systems.

Considerations:

- Higher upfront cost

- Expansion and contraction in extreme climates

4. Cushioned Acrylic Systems

For clubs prioritizing player comfort, cushioned layers can be added beneath the acrylic topcoat. These reduce joint stress and are ideal for senior players or training academies.

In 2026, cushioned systems are gaining popularity due to increased awareness around player injury prevention.

Step-by-Step Pickleball Court Construction Process

Professional pickleball court construction involves several technical stages:

1. Site Evaluation & Planning

- Soil testing

- Drainage analysis

- Layout planning based on official pickleball court dimensions

2. Base Preparation

Two primary base options:

- Concrete slab

- Asphalt base

The base must include proper slope (usually 1%) for water drainage.

3. Crack Filling & Surface Preparation

Before applying coatings, surfaces must be cleaned, leveled, and repaired.

4. Application of Acrylic Layers

- Primer coat

- Resurfacer layer

- Cushion coats (if required)

- Textured color coats

5. Line Marking

Precise measurement ensures compliance with official standards.

Experienced pickleball court builders follow this systematic approach to ensure long-term durability.

Choosing the Right Pickleball Court Material

Selecting the right pickleball court material depends on:

Climate

Hot regions require UV-resistant coatings.

Coastal areas need moisture-resistant systems.

Usage Frequency

High-traffic facilities need reinforced acrylic layers.

Budget

Initial cost vs lifecycle cost must be evaluated.

Maintenance Capacity

Synthetic acrylic surfaces typically require:

- Periodic cleaning

- Minor crack repair

- Recoating every few years

Compared to tile systems, acrylic surfaces often offer better long-term value.

Indoor vs Outdoor Pickleball Court Flooring

Outdoor Courts

- Require UV protection

- Need proper drainage

- Anti-slip texture is critical

Indoor Courts

- Controlled environment

- Less weather damage

- Often installed over concrete slabs

Indoor surfaces may focus more on cushioning and aesthetics, while outdoor courts prioritize durability and weather resistance.

Common Mistakes in Pickleball Court Construction

Even experienced contractors can make errors. Common issues include:

- Incorrect base slope causing water pooling

- Low-quality pickleball court material

- Improper curing time between layers

- Inaccurate pickleball court dimensions

- Skipping crack repair before coating

Working with professional pickleball court builders minimizes these risks.

Cost Overview for 2026

Costs vary depending on location, base type, and surface system.

Major cost components include:

- Ground preparation

- Base construction

- Acrylic coating system

- Labor

- Line marking

Although initial investment may seem significant, high-quality pickleball court flooring reduces long-term repair expenses.

Maintenance Tips for Long-Lasting Performance

To extend the lifespan of your pickleball court:

- Clean debris weekly

- Wash surface periodically

- Inspect cracks annually

- Recoat surface every 4–6 years

- Avoid heavy non-sport equipment on court

Preventive maintenance ensures consistent ball performance and player safety.

2026 Trends in Pickleball Court Flooring

The industry is evolving rapidly. Key trends include:

1. Eco-Friendly Coatings

Low-VOC acrylic systems are becoming standard.

2. Cushioned Performance Surfaces

Focus on injury prevention and player comfort.

3. Multi-Sport Compatibility

Facilities are designing courts that can accommodate tennis and badminton alongside pickleball.

4. Smart Drainage Systems

Advanced slope engineering reduces downtime after rainfall.

5. Custom Color Branding

Clubs are incorporating brand colors into court design.

Why Professional Pickleball Court Builders Matter

Hiring experienced pickleball court builders ensures:

- Compliance with official pickleball court dimensions

- Proper base engineering

- Correct application of pickleball court material

- Long-term durability

- Reduced maintenance costs

Professional construction avoids structural issues that may not be visible immediately but cause major problems later.

Final Thoughts

Pickleball’s rapid growth shows no signs of slowing down in 2026. As demand increases, the quality of pickleball court flooring is becoming a critical factor in facility success.

Whether building a new court or resurfacing an existing one, attention to pickleball court material, accurate pickleball court dimensions, and proper pickleball court construction ensures long-term performance and player satisfaction.

Investing in high-quality surfaces today translates into safer gameplay, consistent bounce, lower maintenance costs, and stronger facility reputation in the years ahead.

For sports complexes, schools, residential communities, and commercial developers, selecting the right flooring system is not just a construction decision—it is a strategic investment in the future of the sport.